ISD has the possibility to carry out 3D scans using the following tools:

• A laser scanner Model Faro Focus S 70 with the possibility to obtain large objects up to 70m

• A manual pulsed light scanners to obtain medium-sized objects

• The photogrametry Kit ScanReference is ideal for creating networks of high-precision landmarks. it is used together with Artec Eva to increase system accuracy

Through these tools and reverse engineering software professional level, ISD is able to build and rebuild anything . The purposes of the 3D scans are numerous , from the reconstruction of appendages to the verification of hulls, from the remaking of fittings to the building of the hull’s geometry for the boat’s tonnage.

project

Emergency Rudder

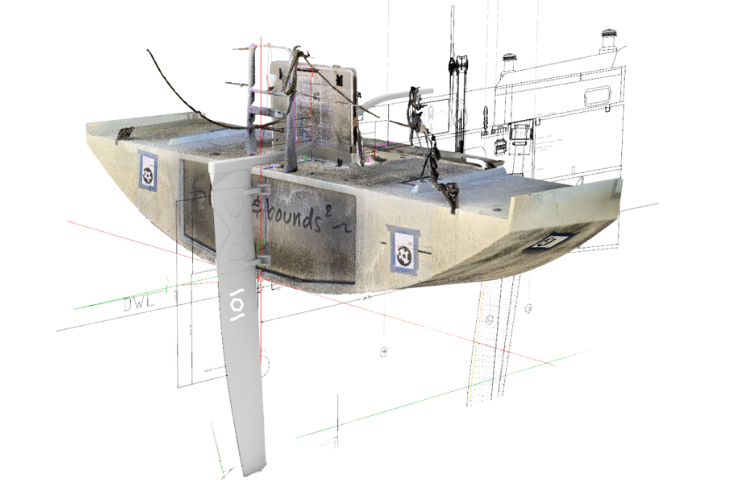

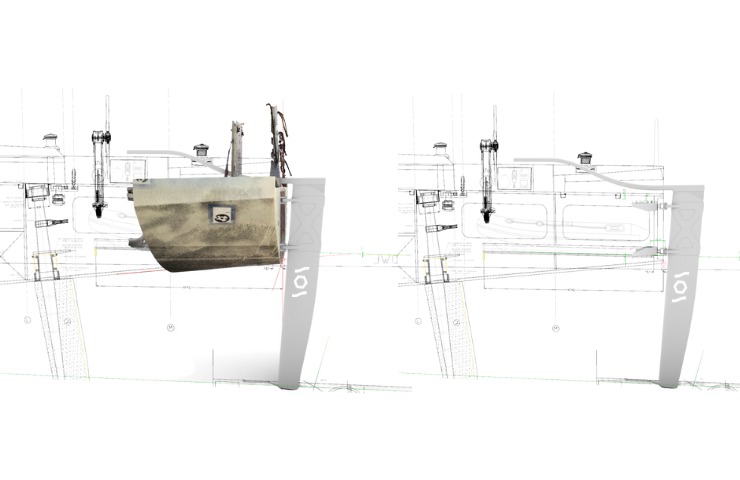

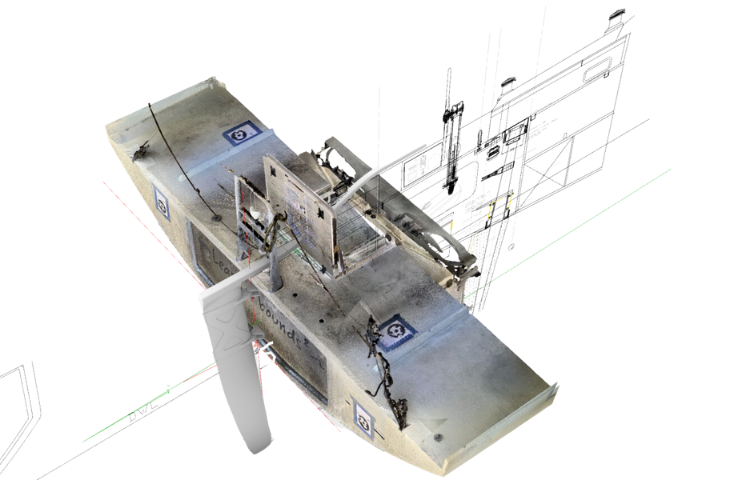

In order to design an emergency rudder for ocean racing, the ISD team scanned and aligned the stern and lazarette of a racing yacht.

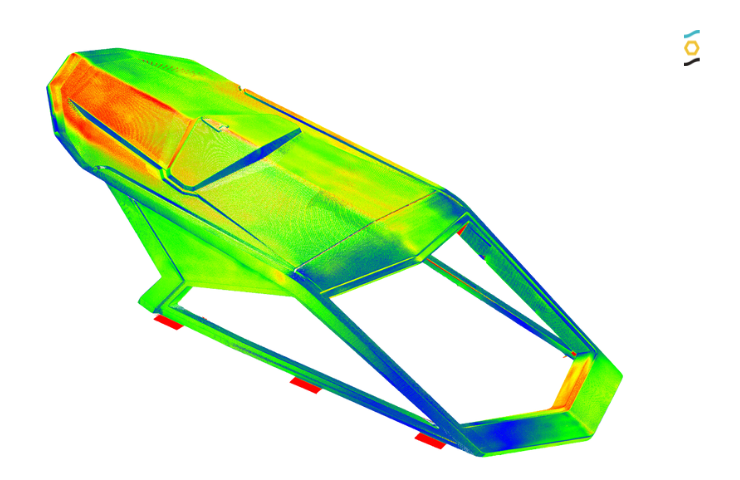

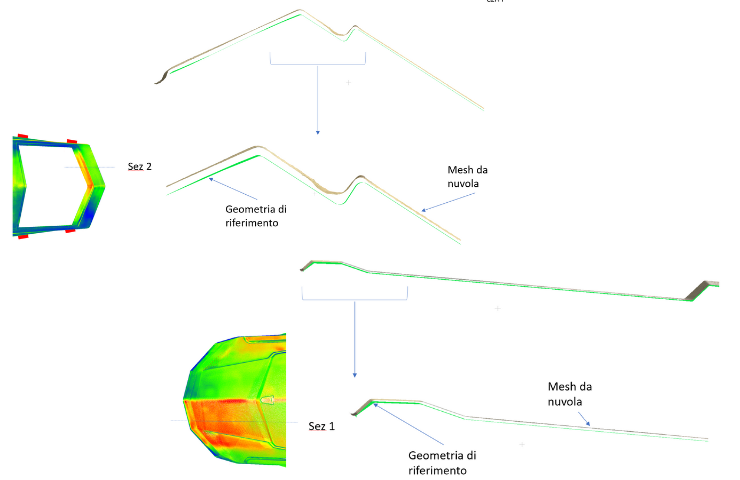

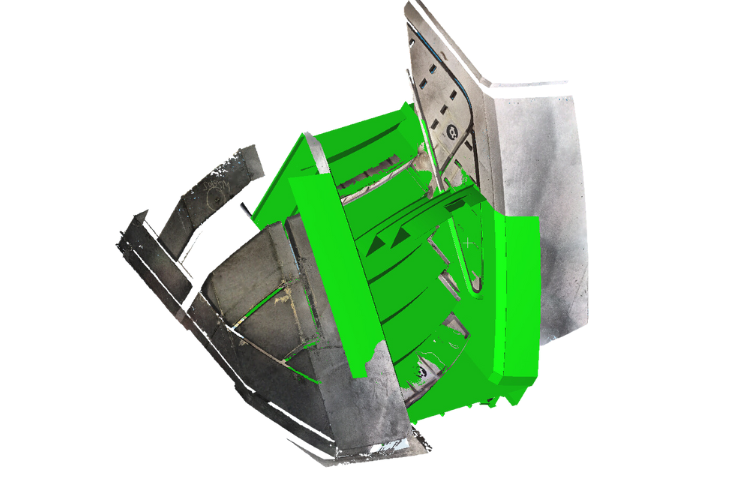

Size Control with scan 3D

We perform scans and alignment between cloud and geometry for size control with final report.

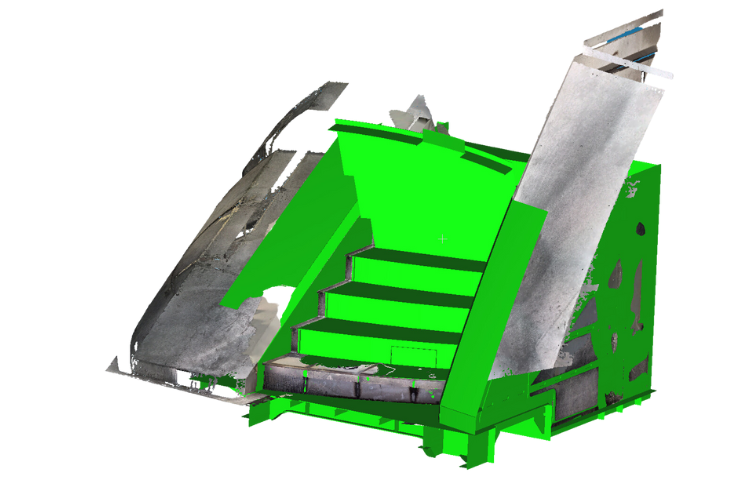

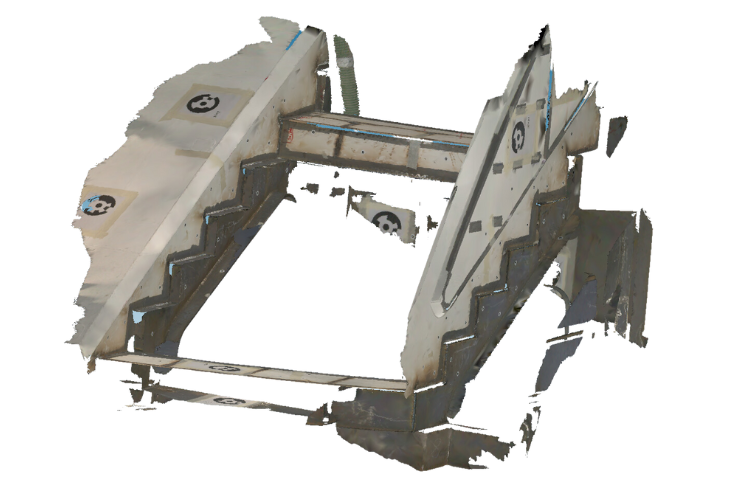

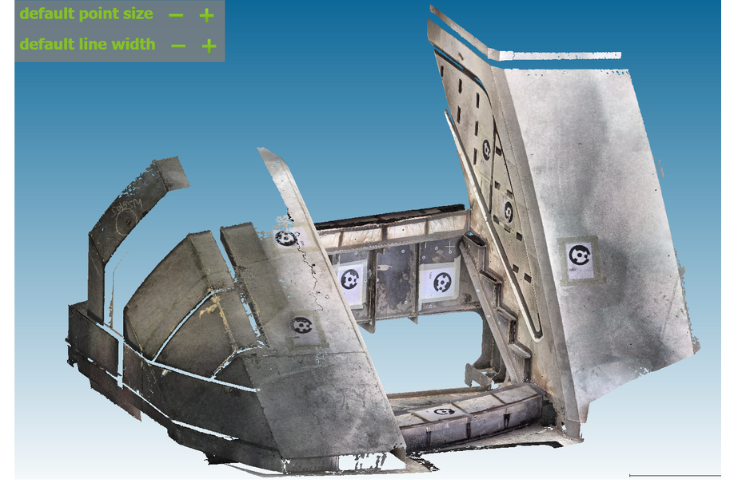

Opening ladder

In this case 3D scanning and alignment to geometry was carried out for the company producing the scale. The work was done with both 3D laser scanners and manual photogrammetry scanners.

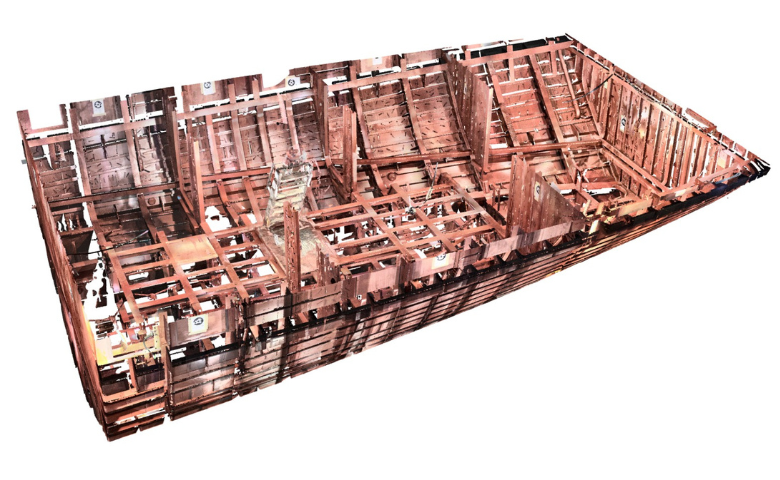

Interiors Scan 3D

We carry out scans for the interior department, this process is usually applied for Megayacht. (we show two compartments before their furniture)

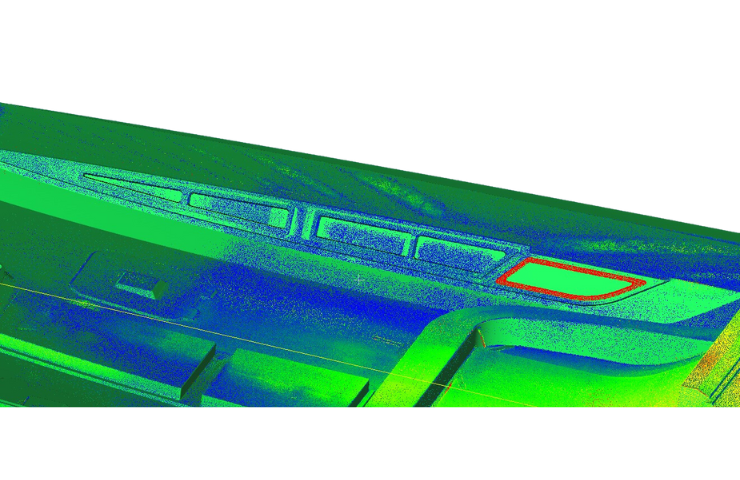

Deck mould scan & Teak Templates

The mold scanning process has various purposes. In this case the scanning has a double purpose: verify the position of the templates by comparing the cloud with the geometry and make the teak’s templates from mesh.

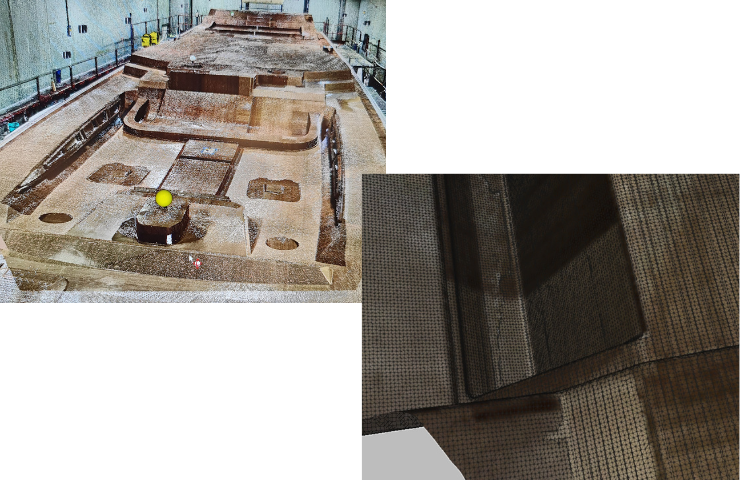

Certification Authority

We carry out scans for the certification of merchant ships. The images refer to a ship of 50m imported in EU territory, which was required a new certification for compliance to European standards.

project

Mould Scan 3D

ISD scans many moulds for various reasons, such as verifying or modifying the geometries required by the project. The technical department also carries out the report for the comparison between geometries given by the customer and the mesh generated by 3d scanning

project

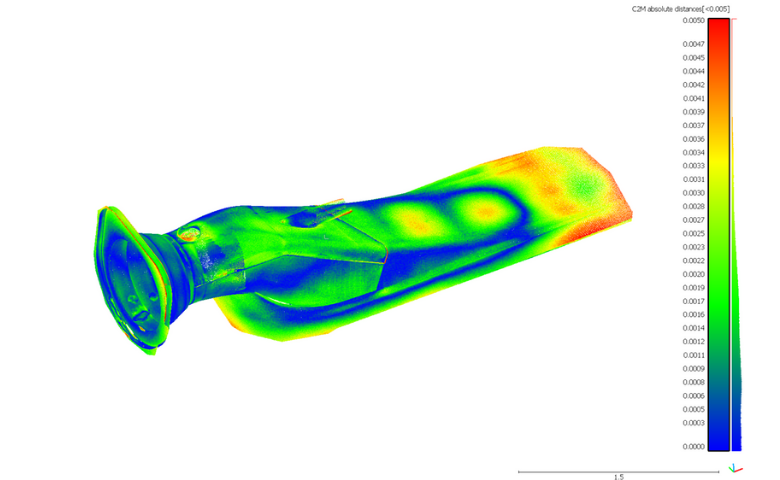

Ducts Scan 3D

The process of 3d scanning and reverse engineering can be used as advanced surface control as reported in this post in which ISD has checked the alignment of 35-meter yacht’s ducts

project

ISD has performed scanning and reverse engineering on numerous keels for the most different reasons such as the modification of the draft or the reconstruction of a damaged keel.

project

ISD performed several deck scans of boats from 60 ‘to 100’ to install flush hatch, or for deck modifications

project

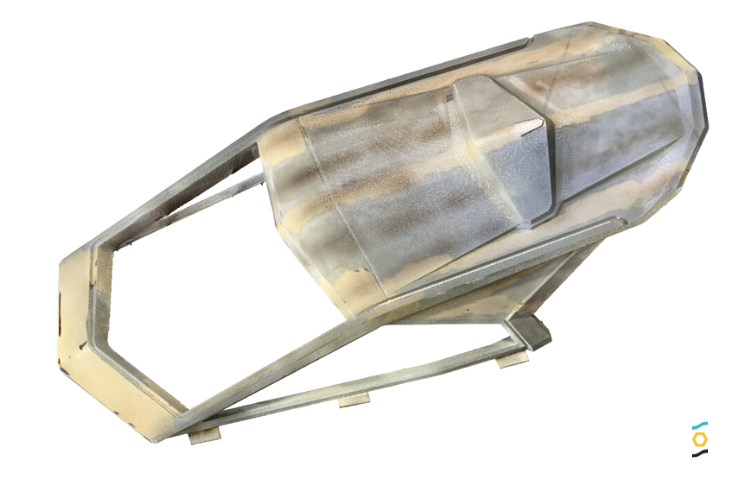

In case of damaged fittings and no longer available on the market, ISD scans the piece to redesign and improve it.

Reported in the figure, ISD scanned and redesigned the new fittings that fit the original mast and that is be able to receive the new cable attachment.

project

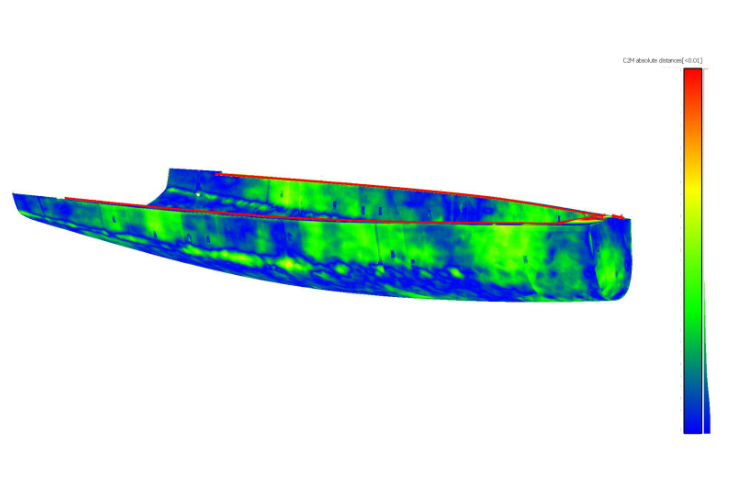

Full Hull

ISD can follow scans of entire hulls to perform the tonnage, or structural changes that fit perfectly the existing one.

project

Product’s Accuracy:

ISD is able to evaluate the geometry’s accuracy of the product compared to the geometry of the constructed or molds

tools

Use of theodolite and laser levels

ISD also checks the keels, rudders, and masts alignment on boats with the aid of the theodolite and laser levels

CONTACT

LOCATION

Via Enrico Mattei 26

Ancona, 60125

SOCIAL

VISIT US