The Innovative Structural Design Team uses the best tools to optimize the design and collaborates at it’s best with the various Yards and Design Studios. Furthermore our technical department has implemented a PDM to optimize the team collaboration and to keep track of the files produced. This allows us to eliminate the errors present when multiple engineers work on complex projects. In the most important collaborations we permitted the ShipYards to access to our database, makeing it possible to share the 3D model with them and allow us to add the parts not modelled by us, typically interiors and systems.

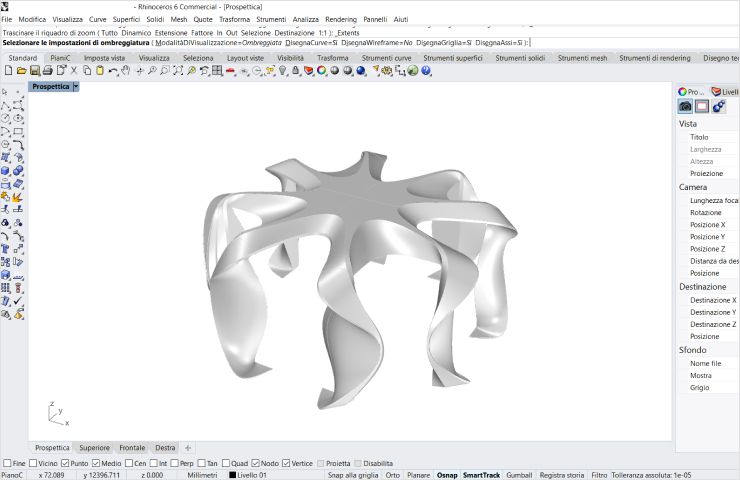

Acquisition of basic geometries

Our typical workflow involves the acquisition of customer’s basic geometries, such as format IGES or Rhinoceros

Final Geometry’s Development

The import of these geometries in a parametric solid modeler, currently SolidWorks and process of the final geometry

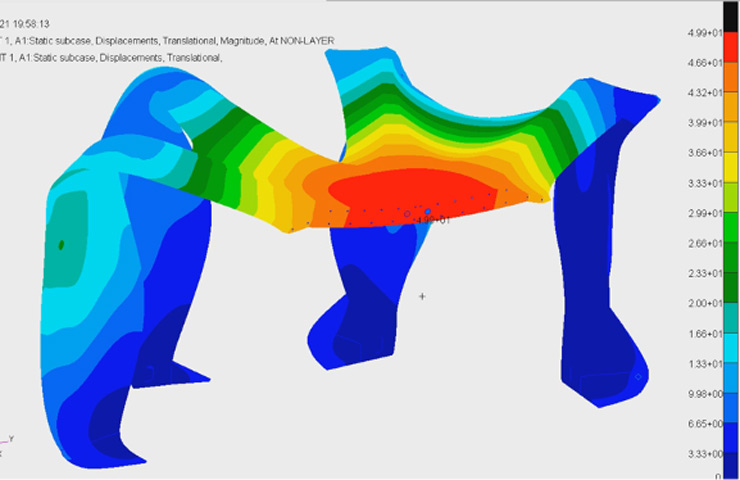

Finite Element Analysis Validation

Validation

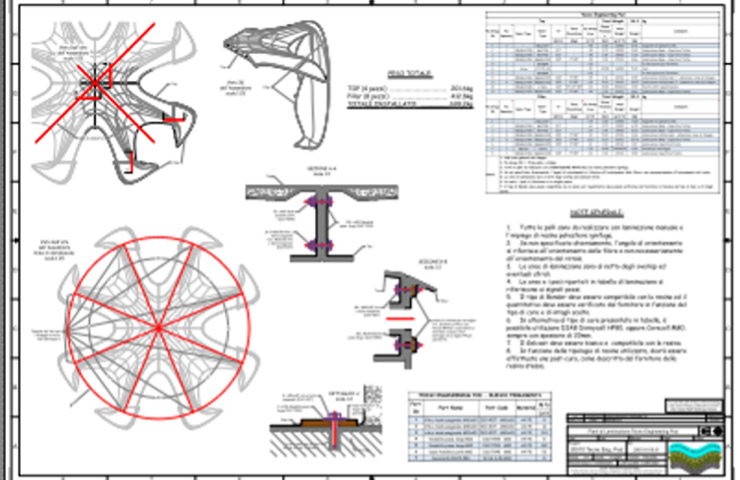

Once the structural check has been carried out, the assembly or component is placed on the technical boards, with all the production’s information, such as:

– Parts List

– Wheight of components and assembly

– List of production materials

– List of commercials and parts to be built

CONTACT

LOCATION

Via Enrico Mattei 26

Ancona, 60125

SOCIAL

VISIT US